Mining, minerals and metals process operations are becoming more complex. The decline of mineral grades, strict regulations, and today’s economic landscape require mining, minerals and metals companies to optimize their operations, processes and use fewer consumables (from energy to reagents) to become more cost-effective. The global mining, minerals and metals industries need new, intelligent, and easy-to-use optimization and process control tools. Our process control solutions provide simple and seamless integration of mining, minerals and metals processing automation. They help align business objectives with requirements across operations and the entire plant.

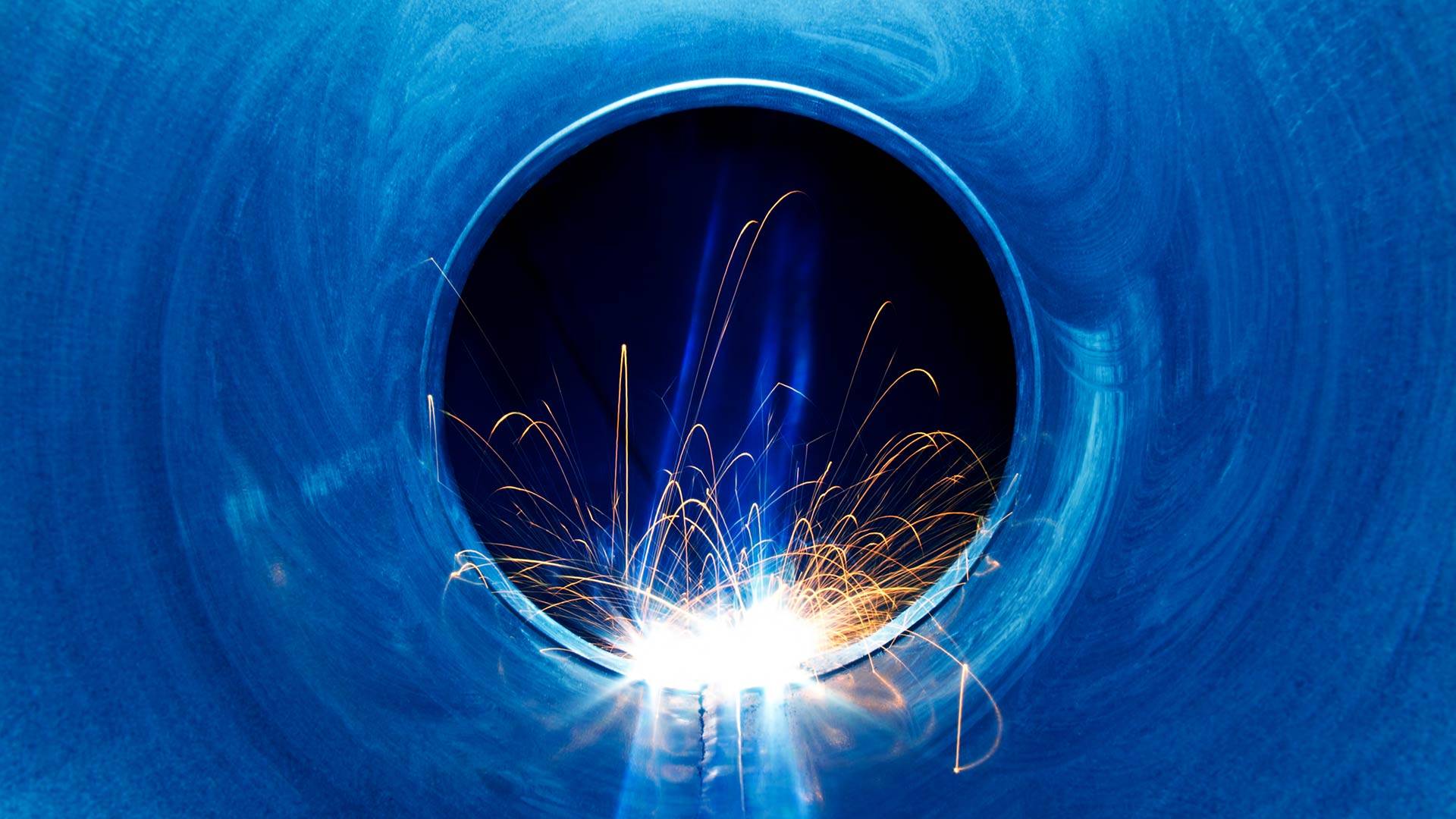

Process automation and control

Automation in the processing and refining of minerals is highly complex. Managing multiple processes and machines requires a multitude of controllers and field devices in a highly distributed configuration.

Find products and solutions

Mining, Minerals and Metals process optimization

The decline of ore grades, increasingly complex mineralogy, and the need for water and energy conservation require greater efficiency from metal and mineral processing plants and operators.

Advanced Process Control stabilizes and optimizes critical production processes and ensures consistent, high-quality output and reduced energy consumption.

Dynamic simulation for engineering and operator training

Unified process plant modeling environment covers the entire lifecycle of the plant, from simulation through system checkout, operator training and start up.

Find products and opens in new Window

Virtual reality immersive training systems

Interactive VR training environment for operators and field personnel.

Find products and opens in new Window