Keep your peace of mind, while we make it easier for you to offer your customers smarter machines that are more efficient and sustainable, even more open and connected, safe, secure, and reliable. EcoStruxure Machine provides machine builders with powerful machine control solutions and opens up new business potential. The payoff is high at every stage of the machine lifecycle. From reducing machine time-to-market by up to 30%, to up to 40% faster machine integration, to cutting time for corrective actions by up to 50%.

Discover our EcoStruxure solutions for Machine Control

Discover software, services, and products for machinery

Meet the next big revolution in machine design

How can you speed up machine design? Virtual simulation and digital design tools are key. In this webinar, see how the new Lexium™ MC12 multi-carrier, coupled with the digital twin technology, is revolutionizing machine design.

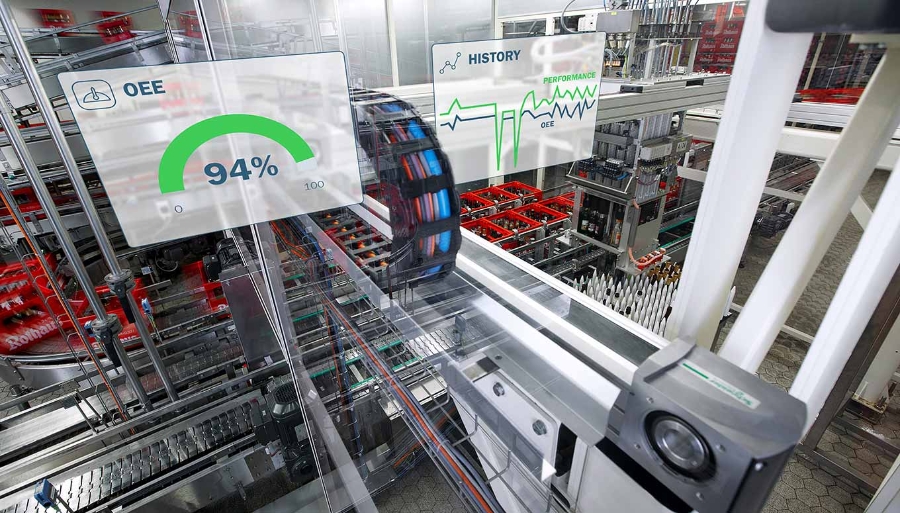

IIoT machine integration with unprecedented efficiency

Breakthrough TeSys island and the ultra connectivity of the Modicon M262 deliver a fully digital ecosystem, magnifying the benefits of new technologies through EcoStruxure Machine.

Explore our customer stories for machinery

Explore the latest insights in machinery

Access mySchneider

Get easy access to the latest digital tools, resources, business services, training sessions, and programs to grow and differentiate your business in the market.

Share your ideas

Continue the discussion with machine automation professionals in the Schneider Electric Exchange Community.